Just register for the free trial below and we will send you everything you need to evaluate QuickBooks Enterprise including 30-day access, sample company files, and the full 88-page QuickBooks Enterprise Guide that details everything that you can do in the software. Free end-to-end consultation and support are included so if you need any help along the way, just let us know!

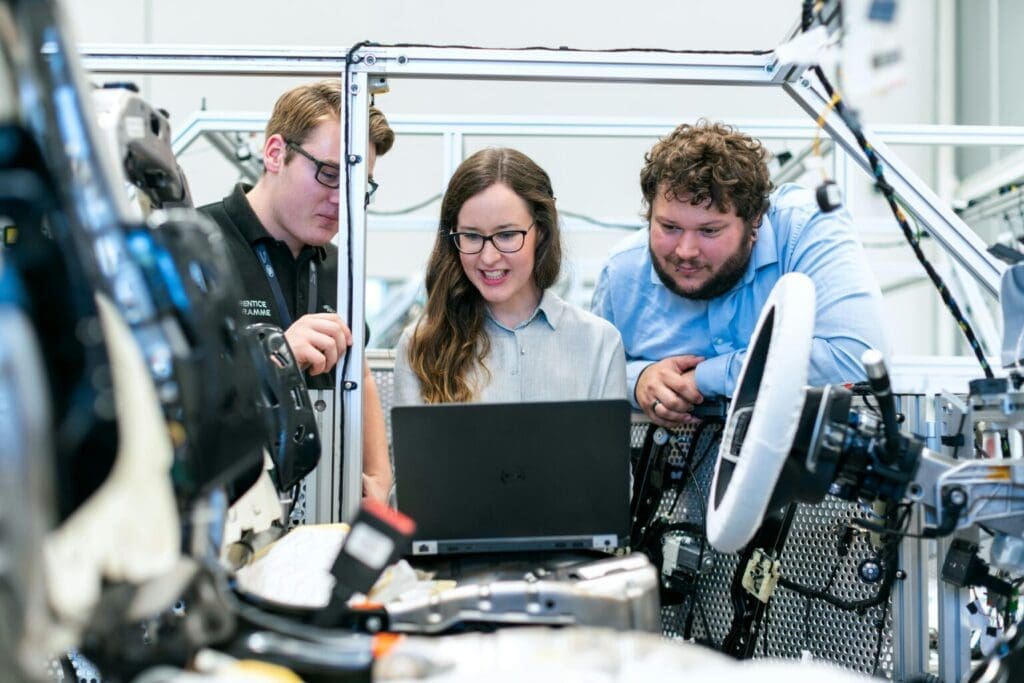

Streamlining Operations: The Role of Barcode Scanning in QuickBooks Enterprise for Manufacturing Businesses

Paygration, Inc.

Barcode scanning in QuickBooks Enterprise offers manufacturing businesses a powerful tool to streamline inventory management, track assets, and improve overall operational efficiency. In this comprehensive guide, we’ll delve into the top key features, how it works, benefits, and scenarios where barcode scanning can revolutionize manufacturing operations.

Key Features of Barcode Scanning in QuickBooks Enterprise

- Inventory Management: Barcode scanning allows manufacturing businesses to accurately track inventory levels in real-time, from raw materials to finished products. It enables businesses to monitor stock levels, receive and transfer inventory, and perform cycle counts with ease.

- Asset Tracking: With barcode scanning, businesses can track assets such as machinery, equipment, and tools throughout the manufacturing process. It provides visibility into asset location, usage, and maintenance history, helping businesses optimize asset utilization and minimize downtime.

- Order Fulfillment: Barcode scanning streamlines order fulfillment processes by enabling quick and accurate picking, packing, and shipping of products. It reduces errors, improves order accuracy, and enhances customer satisfaction by ensuring timely delivery of orders.

- Work-in-Progress (WIP) Tracking: Barcode scanning allows businesses to track WIP items as they move through different stages of the manufacturing process. It provides insights into production status, bottlenecks, and resource allocation, enabling businesses to optimize workflows and meet production deadlines.

- Quality Control: Barcode scanning facilitates quality control processes by enabling businesses to capture product information, inspection results, and traceability data. It ensures that products meet quality standards, regulatory requirements, and customer expectations, reducing the risk of product defects or recalls.

- Customization and Scalability: QuickBooks Enterprise offers customizable barcode scanning solutions that can be tailored to the specific needs and workflows of manufacturing businesses. It scales with growing business operations, accommodating increased inventory volumes, multiple locations, and evolving business requirements.

Learn more about barcode scanning and other advanced inventory features in QuickBooks Enterprise.

If you would like to try the full version of QuickBooks Enterprise Desktop, click here to get a free, 30-day no-commitment trial plus access to the Resource Guide that lists all the features available in Enterprise.

How Barcode Scanning Works

Barcode scanning works by using handheld barcode scanners or mobile devices equipped with barcode scanning software to capture barcode data. The barcode contains encoded information, such as product IDs, serial numbers, or batch numbers, which is transmitted to QuickBooks Enterprise via a wireless connection or USB interface. QuickBooks Enterprise processes the scanned data and updates inventory records, sales orders, or other relevant transactions in real-time.

Benefits of Barcode Scanning for Manufacturing Businesses

- Improved Accuracy: Barcode scanning reduces errors associated with manual data entry, such as typos or transposition errors, leading to higher data accuracy and inventory reliability.

- Increased Productivity: By automating data capture and transaction processing, barcode scanning improves productivity by reducing the time and effort required to perform inventory-related tasks.

- Enhanced Traceability: Barcode scanning provides end-to-end traceability of products, materials, and assets throughout the supply chain, enabling businesses to quickly trace and recall items if needed.

- Real-time Visibility: Barcode scanning provides real-time visibility into inventory levels, production status, and order fulfillment processes, empowering businesses to make informed decisions and respond quickly to changing demand.

- Cost Savings: Barcode scanning reduces labor costs associated with manual inventory counts, data entry, and error correction, resulting in cost savings and improved operational efficiency.

- Compliance: Barcode scanning helps manufacturing businesses comply with regulatory requirements, industry standards, and customer specifications by providing accurate tracking and documentation of product information.

- Customer Satisfaction: By improving inventory accuracy, order accuracy, and on-time delivery, barcode scanning enhances customer satisfaction and loyalty, leading to repeat business and positive word-of-mouth referrals.

How Barcode Scanning Revolutionizes Manufacturing Operations

- Material Receiving: Barcode scanning automates the receiving process by quickly recording receipt of raw materials, components, and supplies, ensuring accurate inventory updates and reducing processing time.

- Production Tracking: Barcode scanning tracks work orders, assemblies, and subassemblies as they move through the production process, providing visibility into production status and progress.

- Inventory Control: Barcode scanning performs cycle counts, stock transfers, and adjustments with precision, minimizing inventory discrepancies and optimizing inventory levels.

- Order Picking and Packing: Barcode scanning facilitates efficient picking and packing of customer orders by scanning barcodes on products, bins, and shipping containers, reducing picking errors and improving order accuracy.

- Shipping and Receiving: Barcode scanning verifies outbound shipments and records inbound deliveries, ensuring that the right products are shipped to the right customers and received from the right suppliers.

- Quality Assurance: Barcode scanning captures inspection data, test results, and quality metrics, facilitating quality control checks and compliance with quality standards.

- Asset Management: Barcode scanning tracks equipment, tools, and machinery, recording usage, maintenance history, and location information for optimal asset management.

Ready to Experience Barcode Scanning in Enterprise?

Ready to revolutionize your manufacturing operations with barcode scanning in QuickBooks Enterprise? Sign up for a free trial or schedule a demo today to see how it works. Additionally, for expert guidance on implementing barcode scanning or optimizing your manufacturing processes, contact the experts at Paygration by calling 866-949-7267. Unlock the potential for efficiency and accuracy in your manufacturing business with barcode scanning in QuickBooks Enterprise!